In our recent podcast, we tackled the critical issue of methane data collection, leak detection and emissions measurement - uncovering the current state of the industry and its potential future directions. Our guest experts, Picarro’s Francois Rongere, Senior Director Solution Architect, Climate and Safety, and Sean MacMullin, Senior Director of Software and Data Analytics, shared their perspectives and offered unique insights into this evolving industry.

Today we aim to break down the complex ideas as we revisit our podcast's key takeaways, understanding methane leak detection technologies, the challenges of measuring methane emissions in a distribution network, the role of data in methane emission measurement, and the importance of measurement-based inventory. Join us as we unfold the insights shared by our industry experts and decode what is fast becoming a new language – the language of methane emission measurements, quantification, and abatement.

Understanding Methane Leak Detection Technologies

00:00:04:00

Tracy: Welcome to the Picarro Community Green Forum, an open space for thought leaders to discuss the ongoing challenges in gas, energy and beyond. I'm Tracy Boyd, marketing director for Picarro and the episode you are about to hear is part of our expert series covering methane data collection, leak detection and emissions measurement. So, to get started at a high level, tell me about the distinct types of methane leak detection technologies available today. Sean, why don't we start with you?

00:00:53:12

Sean: Most methane detectors are based on one of two physical processes. The first being that certain wavelengths of light are absorbed differently by methane than they are by normal air. The second being flame ionization. This is based on the detection of ions that are formed as part of the combustion process. Those types of detectors can be used for many different types of hydrocarbon measurements, but typically use methane as a standard reference.

From those two technological principles, there are two main approaches that are used for detecting methane plumes and performing quantification. Typically, they are split into two categories called passive and active. Passive sensors are positioned at a distance which may be far away from the gas plume, and they measure the reflection or lack of reflection of the sunlight as it passes through the plume and gets reflected back to the source. Typical implementations of these types of passive sensors are mounted to satellites. They could also be on aircraft, helicopters or even in ground-based sensors such as optical gas imaging cameras. On the other hand, active sensors rely on some of these same principles of how methane absorbs the light. But here they require the instrument to shine a laser through a gas sample and then look and see what gets reflected back through the source. In these implementations, the light source, the laser and the detector might be fairly close to the gas plume, such as in a handheld system, or they might be a larger distance mounted to aircrafts or helicopters. And then some of these active sensors actually require the instrument to be directly within the gas plume to make a measurement. Those types of sensors can be built to be very sensitive, measuring, very, very small concentrations of methane. They are typically mounted on drones or in vehicles or on handheld devices.

The Challenges in Measuring Methane Emissions in a Distribution Network

00:03:19:13

Tracy: Okay. So, a lot of options are available out there. Help me understand - how do these technologies fit into the context of measuring methane emissions in a distribution network specifically?

00:03:35:01

Francois: Yes, Thank you, Tracy. I would like to point out that detecting and measuring are two different things. So, let us start with detection first. You may take measurements from a distance and when it is for a satellite, for example, you may have challenges where the visibility and type of clouds prevent the detection itself. That's the first thing you must consider. Another issue is the resolution for satellites. Also, you may have several meters to several kilometers of resolution that can also prevent the detection of small leaks. The detection limit typically for a satellite is about 100 to 150 kilograms per hour, which in terms of cubic feet per hour is about 5000, which for distribution system may not be in the range of what is seen. For a distribution system, ten cubic feet per hour is exceptionally large. For an aircraft, it is about one kilogram per hour, which is about 50 cubic feet per hour.

Another critical point is to consider is the fact that the detection limit itself is hard to qualify. It is a gradient. Matt Johnson recently made a nice presentation about it, explaining how this gradient varies in function of the weather conditions. Also, the wind has an impact on the detection limits, so the detection limit, which is a convenient way to organize the different detectors, must be considered with caution to consider all the different factors that can impact it.

The ability to cover a large enough territory or large enough part of the territory to detect the potential leaks in this area for an aircraft for example, this spot is very narrow and a distribution system is not a linear asset. It's a sort of network. With an aircraft, you cannot really cover with one flight a large part of the distribution system. You need to go back and forth. Of course, in terms of effectiveness, you lose a lot of time. It could be the ideal device for a very small swot - you have to be on the leak to detect it. But the challenge related here is to make sure that you cover everything. And that takes, of course, a lot of time on foot to cover every asset very, very precisely to make sure that you are not missing a leak because you are a little bit away from it.

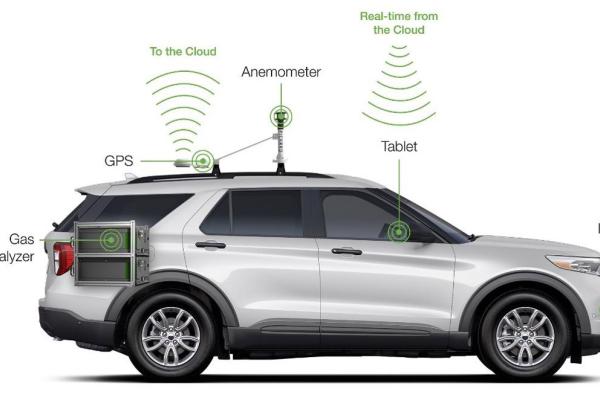

In that context, vehicle-based systems are a natural fit for a distribution system. You have streets of pipes all along the streets. The houses are, of course, along the street as well. You can easily cover the main and the services because the swot is large enough when the wind blows the gas towards a car. And that way you can cover the system to be to be analyzed back.

What we said about detection is one thing, but detecting a leak is not enough to quantify it. More parameters need to be measured. Which requires that you are close to the leak with the ability to detect and measure elements like the wind direction, and environmental conditions so you can determine that actual flow rate of the leak.

The Role of Data in Methane Emission Measurement

00:08:53:13

Tracy: We have covered the diverse types of detection solutions, the pros, and cons of each – and we begin to understand how critical understanding detection limit is. Let's talk about how data needs to be collected and analyzed to measure the emissions of a distribution network.

00:09:27:06

Sean: I would consider this in sort of three approaches in order to measure the distribution network. The first being what are called emission factors. These are engineering estimates, which are typically derived from spot measurements of leaks, most typically through these handheld measurements like Francois just mentioned; you have to be right on top of the leak, but you can then do a direct quantification of it. This historically is how emissions on distribution networks have been reported. While these devices are typically sensitive enough to be able to detect most of the leaks, the approach itself has a large uncertainty as it is not really meant for this scale. So typically, small sample sizes are used. They are not specific to any particular network, but more of an average representation and even in some cases small. Less than ten spot measurements have been used to define the emissions over a full asset class on a on a particular network.

From there we can extend that to a methodology where a direct quantification of part of the network is made and then the result is extrapolated. This is better than a static emission factor approach, but it is still challenging because of the very skewed leak size distribution. You need many samples to characterize and understand your network well. Then it is also challenging to really represent the uncertainty involved in an extrapolation because you need to ensure that the part you measured is statistically representative of the part you you've not measured in terms of asset class, material types, pipe vintages, terrain, etc.

The gold standard approach would be a full measurement, a full direct measurement of the entire network. As Francois mentioned, vehicle based is really a natural choice for distribution network. The technology now enables this to scale in a way it is quick, it is not invasive, and it provides broad coverage of the distribution assets. So, here the vehicle crosses the gas plume within a couple of seconds, it can provide a direct measurement of the flow rate using the concentration and atmospheric conditions such as wind speed and direction.

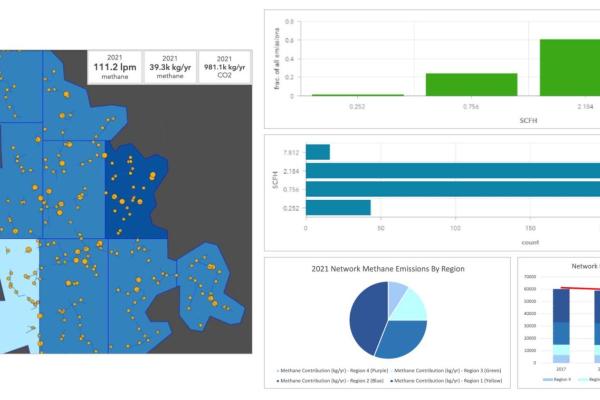

And the most important thing to note about this direct measurement approach is that it really gives you the opportunity to not only report your emissions, but to reduce your emissions. Prioritizing the large logistics for repair is the most effective way to abate emissions. You really cannot reduce effectively what you do not measure.

A little bit more about the methodology - it turns out that for direct measurement methodology there is a bias which is introduced from this direct measurement of a very skewed distribution that tends to give a measurement device a higher chance to overestimate the leak compared to underestimate it. We have developed a method which corrects that bias in a statistical way. And then what you are left with is an uncertainty that is random in nature. And so, that is important because it means you do not need to be accurate on the measurement of a single leak in the network to get a small uncertainty on the total emissions. In a controlled testing for vehicle-based systems they demonstrate typically one order of magnitude uncertainty about a factor of ten on the quantification of a single leak and then once this bias is corrected, this uncertainty then reduces as more leaks are measured. So that can be the order of 10% or so uncertainty. By the time a few thousand measurements are made it gets even down to a few percent, if the order of 10,000 leaks are measured. Then the result here is that you have for each measurement made by the vehicle, you can assign that a certain leak size that will provide a fair estimate of the total emissions when it's summed over the entire network. And most importantly, again, this also enables the framework for quantifying directly the abatement efforts and programs where all the leaks are measured, but only the largest emitters are prioritized for repair.

Importance of Measurement-Based Inventory

00:14:14:10

Tracy: Francois, can you describe for me why measurement-based inventory is so critical? Why is it so important today?

00:14:36:08

Francois: Measurement is critical because of the importance of methane emission in global warming. Most stakeholders really want to have a quantification of the emissions specific to a system or an area. In addition, as Sean has mentioned, it is also a way to drive abatement - to know precisely where to look in order and to act to reduce emissions. There are emerging efforts in terms of standardization and methodology that is underway at GTI as they launch a new activity around Veritas that aim to develop a protocol that can be shared by the different stakeholders to characterize emissions based on measurements. Also, GMP 2.0 includes measurements in this higher level of characterization of the emissions in order to be more specific and better represent different assets and networks. Again, what is important in emission measurements is the ability to reduce and to abate the emissions. And by doing these measurements, we have an opportunity to prioritize the larger emitters and minimize emissions by addressing the larger emitter first.

00:16:37:10

Tracy: I think that's a good place to end. I want to thank everyone for their time today. Some very interesting thoughts on methane detection technology, really discussing the art and science behind how these technologies can work for distribution networks and helping us understand why measuring methane emissions directly is so important.

Conclusion

As we navigated the maze of this new language – the language of methane emission measurements, quantification, and abatement, we hope that it is now less of a foreign tongue to you. In an era where understanding methane emissions is crucial, it is vital that we all strive to speak this language fluently. Thank you for joining us in this exploration and special thanks to our guest experts for their invaluable insights and perspectives.

We look forward to continuing this enlightening journey together, breaking down complexities and promoting a more sustainable future. In our next podcast, we will continue this language lesson by discussing various abatement methodologies available to you and hear from more experts.

Would you like to read more? Register for the Picarro Gas Community! Gain unlimited access to restricted content including playbooks, technical guides and conference panels.