- 北京市朝阳区来广营西路5号院诚盈中心2号楼521室

- 400 048 8082

- china@picarro.com

Quickly Identify and Respond to AMCs Throughout the Cleanroom

Minimize excursions and yield loss

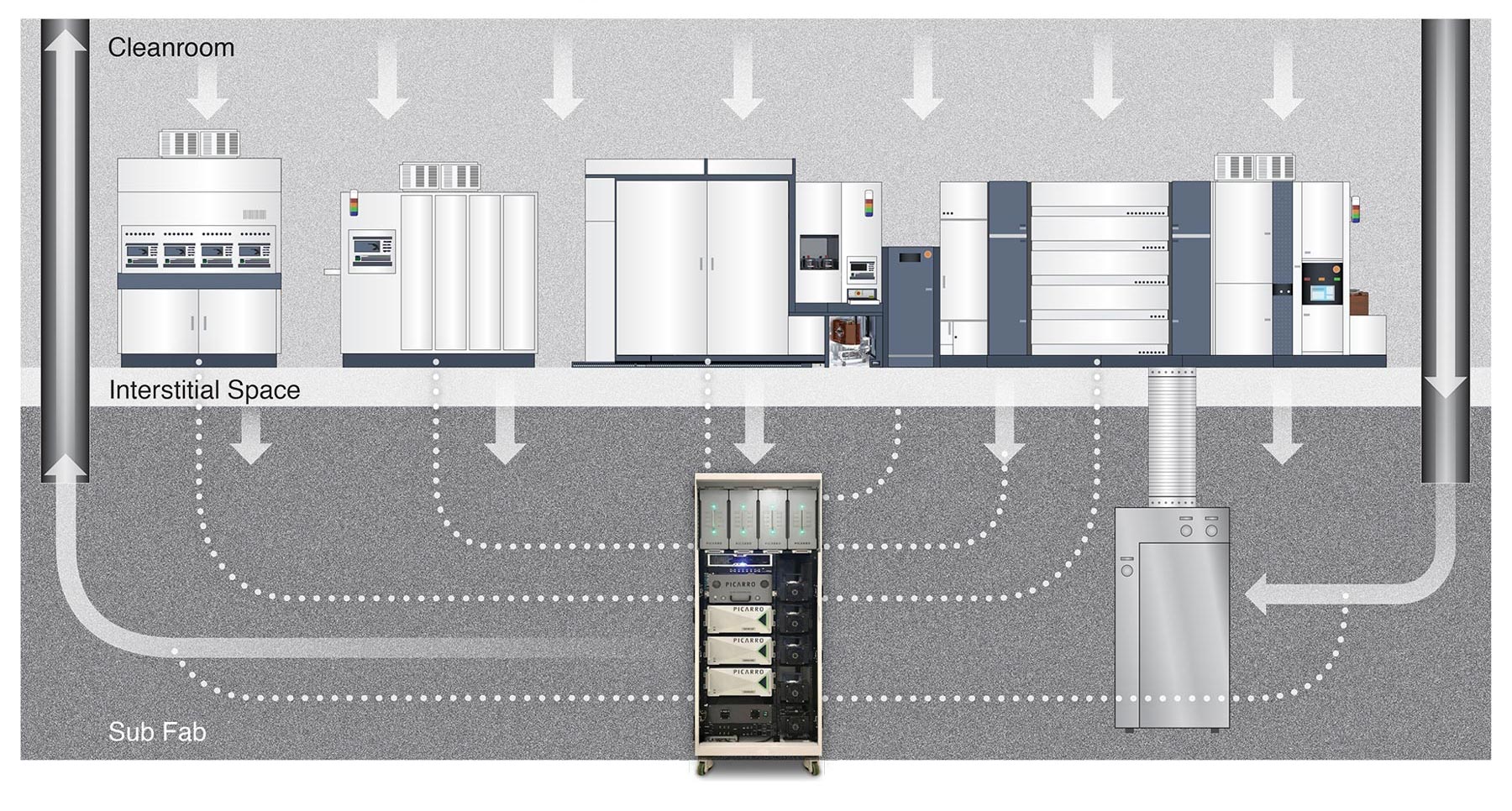

In semiconductor fabs, process tools are spread over large cleanroom areas and multiple floors. Air handlers recirculate most of the air within a cleanroom, which can quickly spread airborne molecular contamination (AMC) to unwanted areas, impacting process steps located away from actual contamination sources. These AMCs can cause a range of problems, including:

- Wafer yield loss due to visual and non-visual defects caused by various acids and bases

- Equipment damage, especially of glass optics and reticles, from haze formation

A resulting fab excursion can mean millions ($) in revenue loss. Thus, it is critical to identify and respond to an AMC event immediately.

The SAM Cleanroom AMC Monitoring solutions from Picarro enable Fab engineers and facility managers to monitor multiple contaminants and take corrective action, if needed, in real-time.

Benefits

- Real-time measurement of multiple acids and bases

- High precision measurements down to parts-per-trillion

- Up to 32 sampling lines that can monitor locations over 100 meters spread across the fab

- Fast sampling options allow clean and purge facilities to quickly clean sampling lines

- No cross-contamination from adjacent sampling lines

Advanced Sampler Design

Traditional sampler systems degrade individual analyzer performance through a linear manifold which limits the gas flow rate to each analyzer. As a result, traditional samplers relegate analyzer performance to the lowest common denominator. Time to detect an AMC is ultimately affected, which can lead to a false alarm or even missing an AMC event altogether.

The design of the Picarro SAM systems is optimized to ensure the highest combined performance, utilizing a patent-pending non-linear multiplexing system that enables high gas flow rates, minimizes cross port contamination, and quickly reports accurate AMC concentrations. The systems can be configured to continuously monitor up to 32 different locations across the fab. Air is drawn into the systems and directed to the Picarro CRDS analyzers. The user can visualize second-by-second data on the GUI as well as detailed trending analysis. The systems can be paired with Picarro analyzers to measure and monitor ammonia (NH3), hydrogen fluoride (HF), hydrogen chloride (HCl), sulfur dioxide (S02), and hydrogen sulfide (H2S). With these systems, process engineers get fast answers to critical questions:

- Is there an AMC excursion?

- Where in the fab is the contamination?

- When did the AMC event occur?

- Is the event reoccurring?

- What may be the potential source of the contamination?

- Does a chemical filter need to be replaced?