- 北京市朝阳区来广营西路5号院诚盈中心2号楼521室

- 400 048 8082

- china@picarro.com

Detect and Quantify Organic and Inorganic Contaminants

Maintain the Lithography Process Integrity

As design features shrink, the number of airborne molecular compounds (AMCs) that can impact semiconductor equipment, processes, and devices is increasing at an exponential rate [citation: IRDS 2020]. Most of these new critically important AMCs are volatile organic compounds (VOCs) such as acetic acid, acetone, isopropyl alcohol, propylene glycol methyl ether (PGME), propylene glycol methyl ether acetate (PGMEA), D3 siloxane, D6 siloxane, hexamethyldisiloxane (HMDSO), trimethyl silanol (TMS), and n-methyl pyrrolidone (NMP).

The chemistry of VOCs in the fab can cause serious problems in the lithography process. For example, haze salt formation is produced by the reaction of ammonia with acids, causing defects on reticles and coating scanner optics. Strong bases such as NMP can cause T-topping defects by poisoning the resist.

Siloxanes in the presence of DUV form silicon dioxide leading to irreparable damage of expensive scanner optics. Fabs need to monitor not just classes of compounds for potential impact on lithography process tools, but also individual species need to be monitored so that targeted control strategies may be implemented.

The concentrations of the VOCs that need to be monitored and controlled are in the parts-per-billion and parts-per-trillion range. Unfortunately, measuring at these low levels is extremely challenging in the fab environment. Most low-level detection techniques, such PTR-MS, are slow, expensive, and cumbersome to use.

Other techniques such as gas chromatography require involved sample preparation and suffer from slow times to detection.

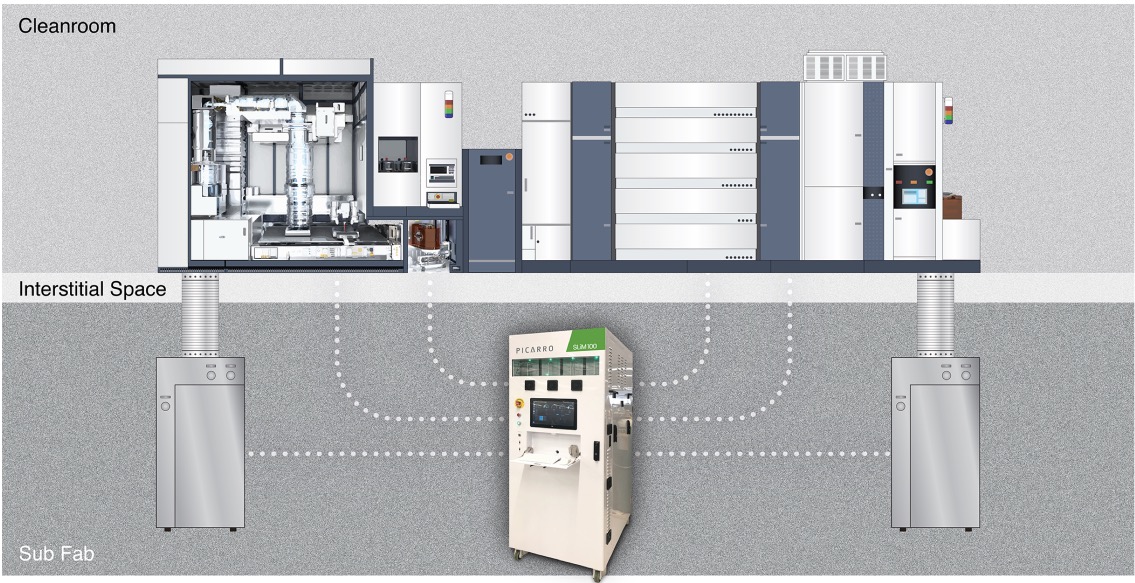

Picarro’s SLiM 100 is a novel lithography process tool monitoring solution that quantifies VOCs at very low limits of detection with good chemical selectivity. The heart of the system is a real-time laser-based analyzer that leverages a new analytical technique called Broadband Cavity Ring Down Spectroscopy (BB-CRDS).

This monitoring system has several features which make it ideally suited to VOC measurements in the production environment:

- Ultra-trace measurements at ppb levels without the need for calibration

- 24/7 operation without user intervention

- Minimal consumables