By: Dave Miller, Business Development Manager, Picarro

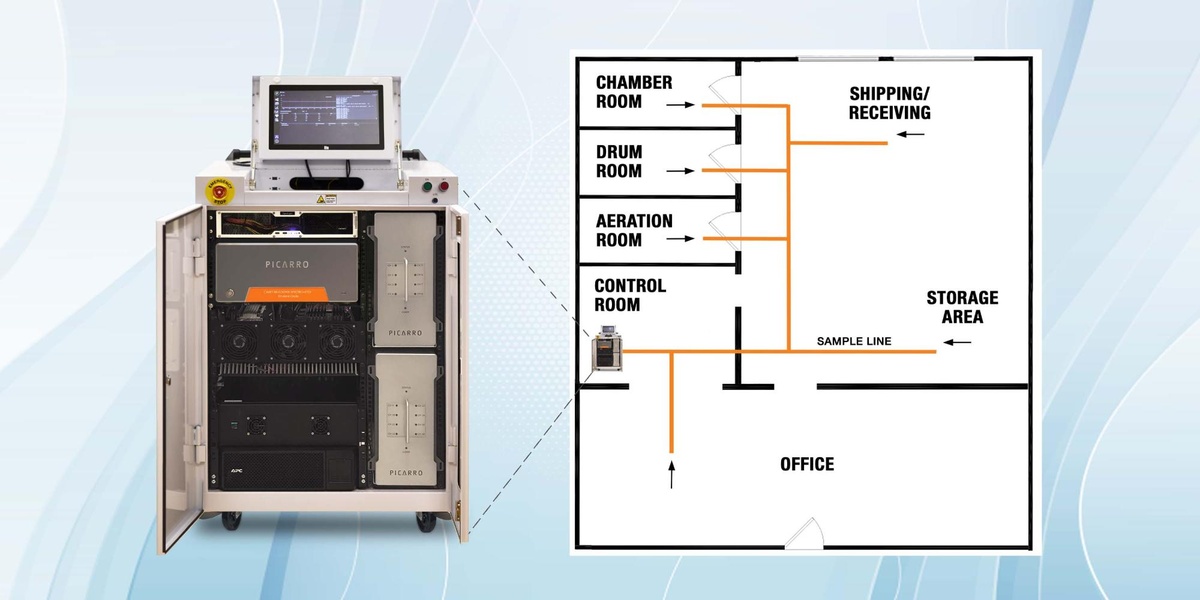

Indoor air quality is highly correlated with the health and well-being of employees in a variety of industries where toxic gases may be present and pose a risk for inhalation. In certain industries where ethylene oxide (EtO) is used, such as hospital sterile processing departments, commercial medical device sterilizers, and spice fumigation, there has been a significant level of scrutiny towards exposure risk in the workplace. Growing concern along with litigation towards companies using EtO has driven the need for precise EtO-specific measurements, without interferences, to analyze multiple sample points across an entire facility (See Figure 1 in diagram above).

Regulatory Drivers

Over the past few years, attention was directed to certain commercial sterilization facilities following the publication of the Environmental Protection Agency’s (EPA) 2014 NATA in 2018, which identified many census tracts throughout the United States for potential cancer risk associated with EtO emissions. In 2016, the EPA effectively lowered their estimated tolerable levels for EtO by several orders of magnitude from previous assessments. This is particularly important for companies using EtO, as other regulating agencies across the globe are also expected to re-evaluate exposure limitations. For example, the Occupational Safety and Health Administration (OSHA) recognizes that many of its permissible exposure limits (PELs) are outdated and inadequate for ensuring the protection of worker health. Most of OSHA's PELs were issued shortly after the adoption of the Occupational Safety and Health (OSH) Act in 1970 and have not been updated since that time. Many companies are taking the prudent approach to modernize their facilities’ air quality monitoring systems with precise and targeted technology to gather actionable and defensible data in real-time.

Picarro’s Solution

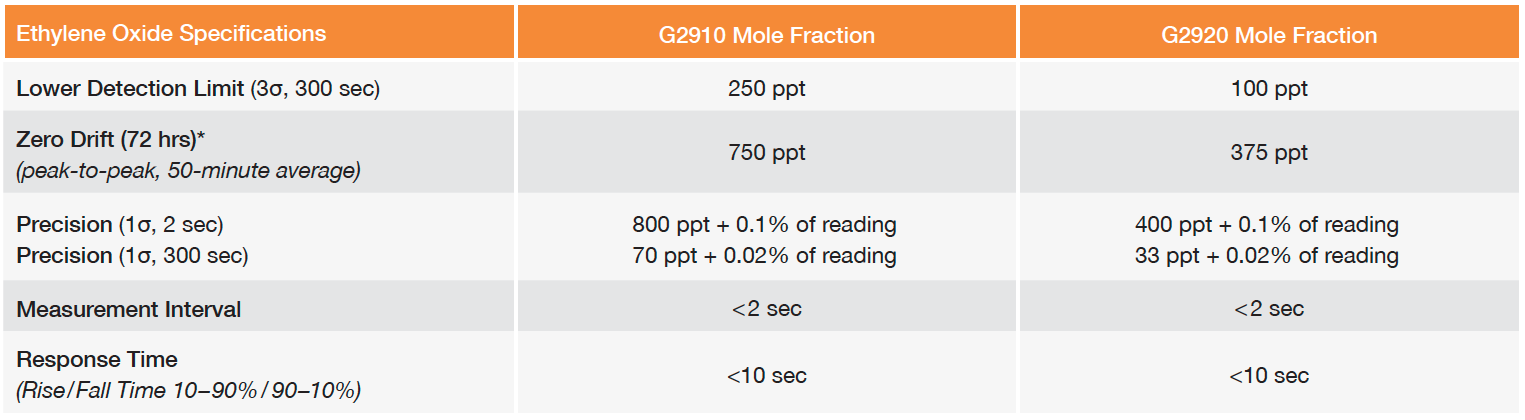

As a leading provider of real-time analyzers for monitoring concentrations well below OSHA action levels, Picarro has designed its G2910 and G2920 EtO analyzers (Figure 2) with both specificity and sensitivity to low levels of ethylene oxide -- down to parts-per-trillion (ppt) -- without the need for preconcentration or chromatographic separation. In sterilization or chemical manufacturing facilities, EtO concentrations can quickly change around process areas that are dependent on a variety of engineering and administrative controls for fugitive emissions capture and air exchange. The rapid response to dynamic concentrations makes Picarro Cavity Ring-Down Spectroscopy (CRDS) a robust solution for industrial sites where personnel need real-time data to react to health risks.

Figure 2: Picarro G2910 and G2920 EtO Analyzer Specifications

With multiple indoor monitoring solutions commercially available for EtO, it’s important to put the technology comparisons into perspective. Picarro analyzers alleviate many of the issues found with complex, less precise technologies by addressing the following performance metrics:

- Lower limit of detection and wider dynamic range enable precise detection and quantification of all fugitive emissions

- Fast sampling and switching speeds via an integrated multiplexer that maintains continuous sample flow from each location for less cycle-time as compared to other technologies

- Simple integration with existing data historians and less maintenance for a lower cost of ownership

- Greater stability and fewer calibrations create an industry-leading operational uptime

- Higher-confidence, real-time data access, without the need for post-processing or interference correction from complex peripherals

- Higher precision and sensitivity that is future-proof against regulatory change

Many facilities are at a critical point where the reliability of passive monitoring devices fail to meet the need of proactive safety programs and older sensor technology, such as electrochemical, photoionization detector (PID), Fourier-transform infrared spectroscopy (FTIR), and gas chromatography (GC) exhibit false readings due to interference from water vapor, equipment exhausts, and other non-VOC hydrocarbon fumes. In addition, many incumbent technologies are complicated, expensive to maintain, and require large amounts of downtime due to frequent maintenance.

With clear advantages in measurement speed, sensitivity, and reliability over traditional technologies, Picarro EtO analyzers (Figure 3) provide an excellent solution for workplace indoor air quality monitoring. Please visit our EtO product information and industrial monitoring pages to learn more.

Figure 3: Picarro G2910 Stack and Indoor Air Quality Analyzer enables quantification of EtO from stacks, abatement systems, sterilization rooms, aeration warehouses and building ventilation.

About the Author

Dave Miller supports Picarro as Business Development Manager within the Environmental function with a strong focus on growing the application of our hazardous air pollutant analyzers. He has a diverse background with various regulatory and project management roles including the installation and operation of emissions controls, process, continuous, and fence-line monitoring. His previous experience also includes managing environmental regulatory and ISO 14001 programs, public water and wastewater infrastructure project management, and legislative affairs work.